Hey, tldr: I need help, because my D6 print is stretched/dented and faces are sunken and I don’t think it’s because of supports anymore.

I am a beginner 3D printer. I have Saturn 2 printer and use Elegoo Water-washable 8K resin. I finished calibration using Cones of Calibration and my best result was with 2.4s exposure for normal layers - best result means: all success cones, no failure cones and arrows on the side are fully readable and texts are great quality.

Furthermore, I use LycheeSlicer and resin settings:

- 35s bottom layer exposure,

- 2.4s normal layer exposure,

- speeds: lift 65 and retract 180,

- wait before print: 1s

My first print after calibration was D6. Here, I want to assure you, that the model is 16x16mm, and it’s a 100% cube - the model is not the problem.

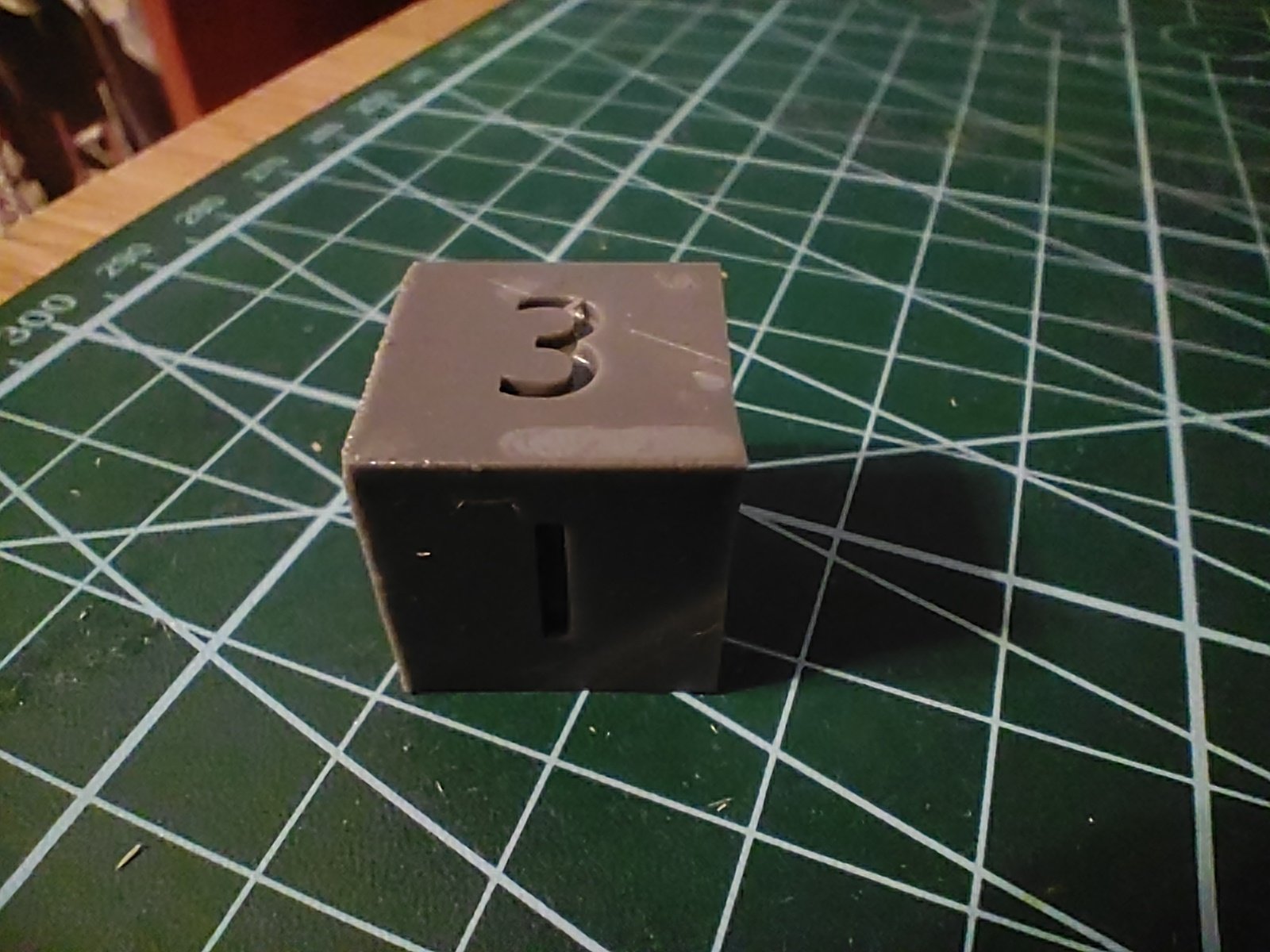

I added supports to the model in Lychee and printed. It came bad as you can see in the pictures:

I printed this D6 with:

- 2.4 exposure

- 3.5 exposure

Both look the same in the matter of their shape.

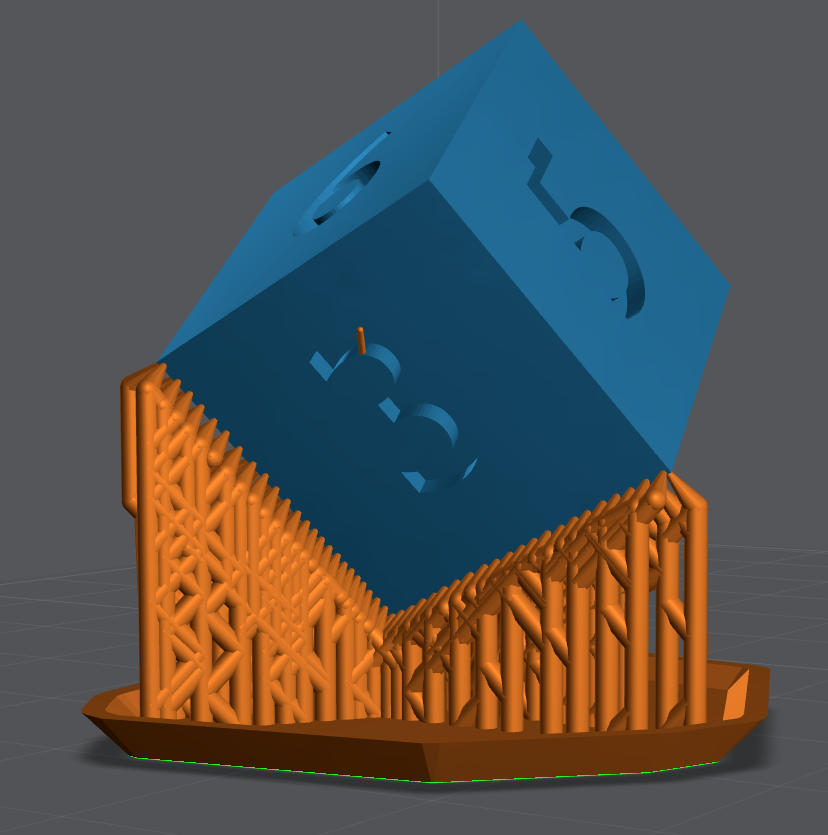

It seems that some sides are stretched and some are less than 16mm long. Some sides are curvy, some faces are sunken and some has like level-shifting. Below you can see some images of the model with supports.

I gotta say - I’m not expert in supports and I know these are not ideal, but they were easy to do and to get rid after the print. I thought what’s happening is the fault of the supports, but so many supports should be ok I think… I saw some tutorials that people made for supports and those aren’t so different from their.

I also printed another model - little Bulbasaur - and it came perfect with exposure 2.4s for normal layers and in two layer height versions: 0.03 and 0.05 mm:

I clearly need help and if anyone has an idea what can I change - feel free to shoot.

EDIT 1:

After @Shialac comment, I added many supports to any face that leans toward down at any angle:

There are many improvements in faces that lean up, but there’s still this little stretch in the common tip for faces 1,2,3… It looks like the whole dice is too heavy and it pulls it from this tip. Do you have any idea how can I fix this?

huh, interesting…

Maybe the solid flat surface sticks too strong to the FEP? You might try to print the die hollow (dont forget to add a small hole at the lowest point)

You could also try to apply PTFE-Spray to your FEP before you fill it with resin to lower its adhesiveness

(I would try hollowing first since you wont need anything extra)